Supply Chain Monitoring: Returnable Container tracking

Background A manufacturer of highly explosive chemicals needs to account for every gallon of chemical whether it’s in process, storage,...

Enabling real-time visibility, automation, and data-driven control across modern supply chain operations.

An overview of the key trends driving RFID adoption and the opportunities they create for efficiency, visibility, and long-term scalability.

Real-Time Tracking

& Visibility

End-to-end, real-time tracking across manufacturing, warehousing, and distribution for complete supply chain transparency.

Automated identification reduces manual errors, improves inventory accuracy, and enables dynamic stock replenishment.

RFID data integrated with IoT and analytics delivers actionable insights for demand forecasting and operational optimization.

Cold Chain & Perishable Monitoring

Ensures temperature compliance and safe handling of food, pharmaceuticals, and other sensitive goods.

Improves asset tracking, reverse logistics, and recycling to reduce waste and support circular models.

Lower deployment costs and scalable infrastructure make RFID viable for businesses of all sizes.

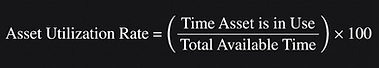

To measure the real impact of RFID adoption, organizations must track clear, outcome-driven performance indicators. These metrics help evaluate improvements in inventory accuracy, operational efficiency, asset utilization, and cost control—while providing a measurable basis for ROI and continuous optimization across the supply chain.

RFID KPI Calculation Models

Compare post-RFID performance with baseline data to assess improvements, identify gaps, and understand the causes of unexpected outcomes.

Continuous Improvement

Use insights to address bottlenecks, optimize RFID deployment, train teams, and continuously track KPIs to sustain performance gains.