iVEDiX transforms the experience of collecting, aggregating, visualizing, and analyzing data from connected assets, sensors, and systems.

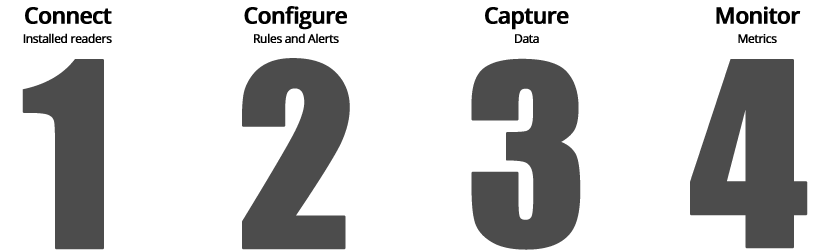

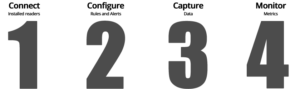

Tags and Sensors produce billions of data points from location information to temperature and vibration readings constantly. Our software has the ability to read this data as soon as it’s generated using any one of the multiple protocols that are part of the IoT industry-standard today (GPS, RFID, Bluetooth, LORA, etc). The iVEDiX platform can blend tag/sensor data with traditional streams of data (ERP, MES, DWH, etc.) on the fly, in real-time, to provide incredibly powerful insight on how your business is really operating vs perception.

The CORE part of the Platform has the ability to consume this data/information and tag it with rules, thresholds, workflows, and exceptions. Notification parameters can then be configured to transmit exceptions to the rules via text, email, app-badges, or reports.

Visualizing IoT data in real-time and in aggregation, then marrying that granular detail with your over-arching business goals. Tying your entire workflow together. Putting digital transformation into action, from the shop floor to the C-suite. That’s the power of iVEDiX.

Industries

Asset Tracking for

Manufacturing

Automating tracking of returnable containers and other high-value assets allows manufacturers to effectively and efficiently track the location of critical parts during each stage of their work process – and to solve numerous supply chain management challenges at the same time.

Today’s most innovative manufacturers are turning to IoT technology to accomplish this task. An IoT enabled material tracking system allows for automatic, cost-effective tracking of assets (pallets, racks, totes, drums and more), providing real-time data on location, status, state, certification, history and more. Leveraging our Process Flow and Rules engine, configure granular sub-processes to track as part of the asset’s lifecycle (i.e. prep to clean) and trigger alerts and notifications via customizable rules.

Link to this use case

Asset Tracking for

Safety & Security (Vehicle)

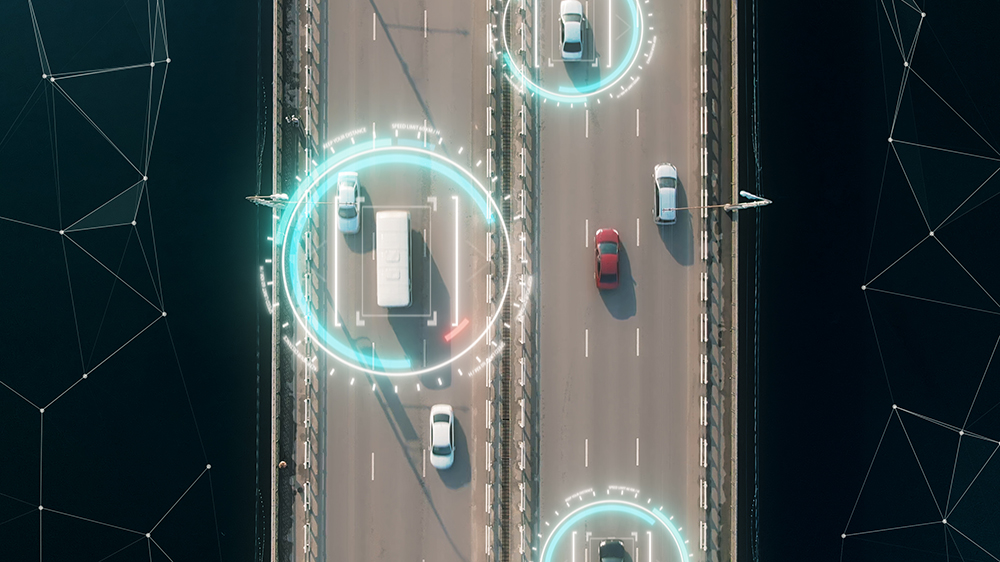

Facilities must gain a real-time ability to monitor assets in motion (people, vehicles, devices etc). Location, distance/time traveled, geofencing, time in place (dwell). All should be from a single pain of glass, without the need to monitor numerous video cameras or endure the cost of 24-hour personnel to staff posts.

Location-based rules should trigger pre-configured actions like notifications and alerts. The dynamic ability to configure and aggregate sub-process flow interval tracking that fit your specific process,

Varying technological options can easily cover more locations than a manual process, but the unique nature of an underground roadway with dense concrete walls limits the line of site for some automated solutions. See how we solutioned this unique scenario to give our partner the ability to maximize operational efficiency while enhancing security and enabling action.

Link to this use case

Featured Resources