Asset Tracking and Actionable Analytics Case Study

Case Study: Manufacturing / Pharma / Container

A global manufacturer needed to:

o Track inventory to minimize container losses/damage.

o Stay compliant with regulatory / customer mandates on container certification.

o Improve production and supply chain cycle times.

o Improve and optimize recycle times for containers back to recirculation.

o Enhance safety for its employees.

o Integrate with SAP ERP-ECC6 system.

o Provide on-demand transparency of the process/metrics to regulators and customers.

o Scale across all global plants/sites on demand.

The solution:

▪ RFID tagged assets and asset tracking

▪ Process mapping including digital zonal location and process state markers

▪ Real-time alerts and notifications

▪ On-demand data and reporting for compliance and audit

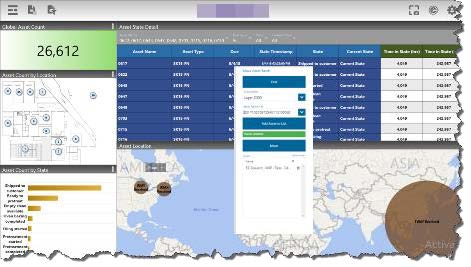

▪ Robust analytics serving actionable intelligence

▪ Ubiquitous access – mobile/desktop

Benefits of the Solution:

▪ Locate Assets in Real-Time

o Where is this asset right now? We need it. Active RFID Sensors were placed throughout the factory and tags were placed on each Container.

▪ Real-time and Profile-based notifications.

o Multi-channel notifications (email, SMS or ‘In-App’ when there are issues in Production as it happens or before (based on thresholds/conditions) in order to facilitate enough time for an intervention. Make the right people aware of issues while there is still time to affect outcomes.

▪ Bundle Analytics

o ‘Out Of The Box’ robust analytics and reporting.

▪ Shave Cycle Time

o Look at the data in aggregation so that process flow improvements can be made.

▪ Integrate with SAP

o Receive data feeds from SAP to kick off processes and update status. Send asset movement history and other metadata back to SAP.

▪ Experience the Interface

o For the user on the Production Floor, the user experience has to be mobile, intuitive, and accident-proof. For the Data Analyst in the office, it has to allow for rich data exploration and discovery on the desktop.

▪ Improve Safety

o Knowing the history of the asset, its contents and the process state reduces safety incidents.

▪ Enhance Physical Security

o If the asset is in the wrong place at the wrong time, people can be made aware.

• Experience Digital Transformation

o Replace your paper processes with Digital Footprints for better process improvement, clearer analytics, and trackable compliance.

• Reduce Loss

o With real-time asset location, misplaced assets are reduced.

• On Demand Scalability

o Configure new locations and rules on demand to scale anytime, anywhere.